The Function of Different Sieve-plate

Updated: Wed, Sep7, 2016

By Mega Young Screen Technology Co., Ltd

We have published with five kinds of sieve-plate profile introduction in the last article. This time, Mega Young will give the role of different sieve-plate.

1. Bar sieve-plate. The mesh size is the length of each bar, bars are parallel arrangement. Bar sieve-plate is applied in stationary screen and heavy vibrating screen.

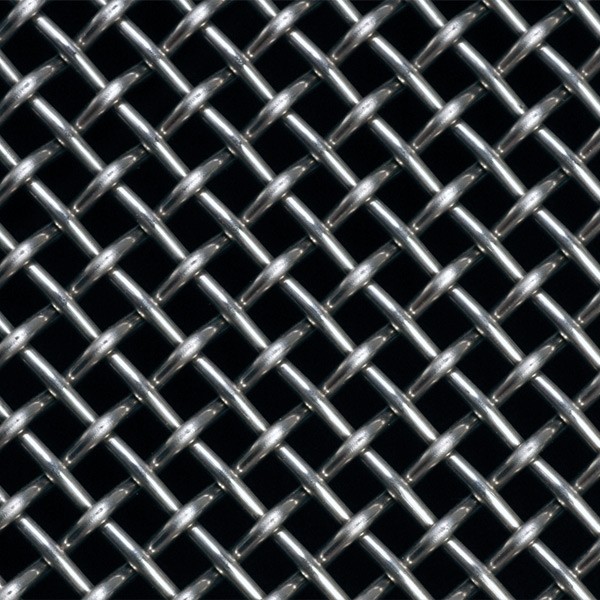

2. Woven sieve-plate. Its advantages are light-weight, high porosity, and a degree of flexibility, but the short lifespan is woven sieve-plate shortage. It suits for middle or fine granular material screening.

3. Perforated sieve-plate. Rectangle perforated sieve-plate is more suitable for the high water content material than the round and square plate, especially in effective sifting area, output and weight, etc.

4. Slot sieve-plate is for dewatering desliming and sculting of middle even fine granular.

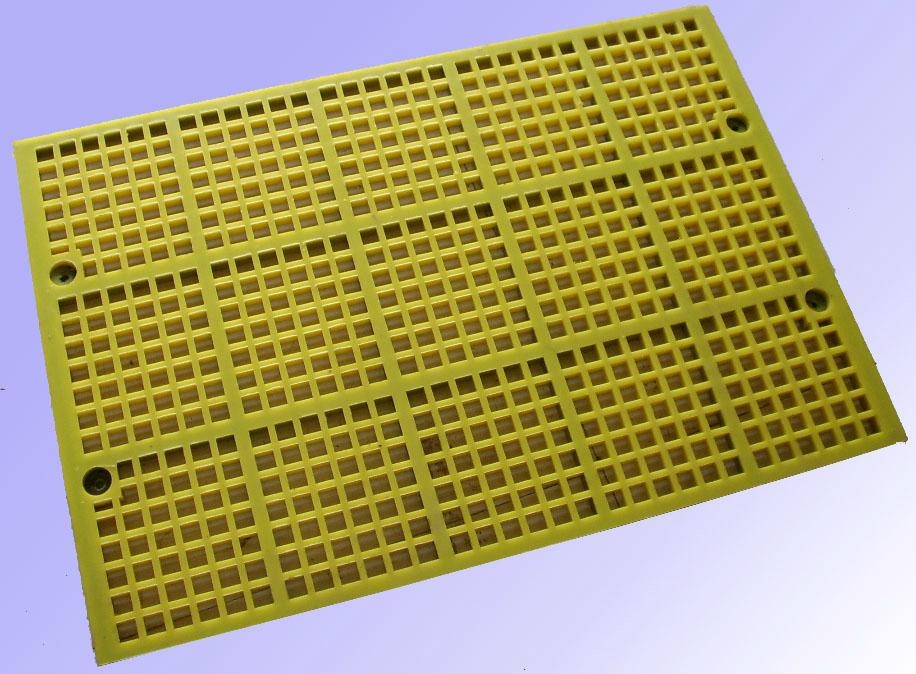

5. Polyurethane sieve-plate advantages are oil resistance, wear-resisting, bactriostasis resistance, ageing resistant, etc. Polyurethane sieve-plate is can save the equipment lifespan, reduce the producing cost and reduce noise efficiently, it is usually used in mining, metallurgy, petroleum, chemical and other areas.