Operation Cautions of Drum Vibrating Screen

Updated: Fri, Sep 02, 2016

By Mega Young Screening Technology Co., Ltd

Drum sifter mainly function is screening materials, there is a lot of dust in some materials, the dust-extraction unit should be applied on the basis of original equipment. User should get hold of opening machine’s order when the machine is used, first you need to start the dust-extraction unit, and then launch the drum vibrating screen, finally, add the materials, it is the opposite way to deal with the these steps when stopping machinery.

Manufactures provide a part of lube to users for test-run a machine; gear lube should be added when the machinery starts to run, in order to avoid the damage of gear after a long service.

User need to check and tighten all bolts, especially motor bolt and reduction gear bolt, when new equipment running 10-20 hours.

In some particular situations, drum sifter has been warped in the process of transportation, thereby debugging machine is very important, it should be handled if there are any problems, otherwise, it will damage the vibrating motor.

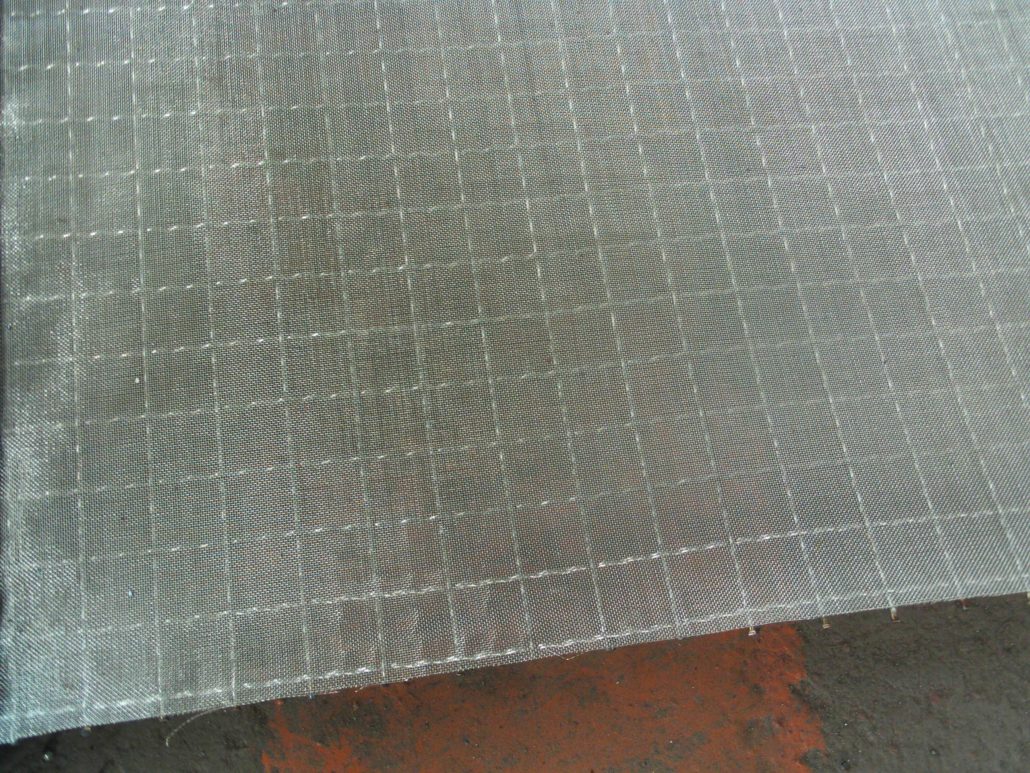

The bearing fittings, seal ring and sieve should be replaced in time when they abrasion.